-

图文详情

-

产品属性

-

相关推荐

- 适用范围(Scope):

本规格书适用于RTI-10 SERIES FUSE系列保险丝。

This Specification apply for RTI-10 series fuse.

2.适用文件(Apply the standard):

2.1符合IEC60127/UL248标准。(ApplyIEC60127 and UL248standards)

2.2标识(Approval marking):

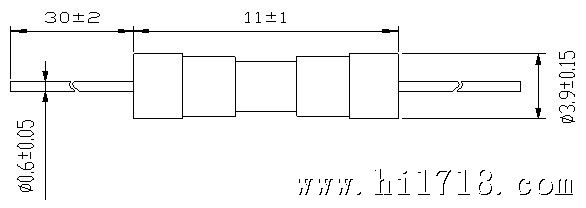

3.外型尺寸(Size)

4.材料(Material):

部件(Parts) | 材料Material |

铜帽(Copper cap) | Ni plated brass |

管(Tube) | (√)Glass tub()Cermic tube |

引线(Lead pigtail) | Coppe plated tin wire |

熔断体(Fusing wire) | alloy wire |

4.1玻璃管Glass tube(陶瓷管Cermic tube)

玻璃管或陶瓷管必须无缺陷、缺损、凹陷,明显脏污。(The glass tube should be of no blemish, no damage and no pollution.)

4.2铜帽(Copper cap)

每个铜帽必须焊接牢固,导电性良好,表面镀层结合牢固,不易脱落,无损伤。浸入温度为15-35℃的水中24小时,按标准的要求施加轴向拉力5N,并持续1分钟,不会出现松动、松脱的情况。(Every copper cap must be welded tightly and have good electric conductivity. Also the outer coating can be very tight, perfect and not easily fallen off. It can be immersed in water with temperature between 15-35℃for 24 hours. Every copper cap can stand axial pulling force 5N exercised by special equipment for minute.)

4.3焊锡(solder)

焊料应具有良好的电接触性能,并且在正常使用时不应有熔化的迹象。(The welding materials should have good electric conductivity and not be melted at normal using.)

4.4引线(Lead pigtail)

引线采用镀锡铜线,具有良好的可焊性能,导电性能。可焊性符合GB2423.28-82 /IEC68-2-20之标准。引线的尺寸以及形状可以根据客户的不同要求制作。(Lead should be tinned and have the performance of perfect welding and good contact with electricity.Jionting performance apply for GB2423.28-82/IEC68-2-20 standard)

4.1玻璃管Glass tube(陶瓷管Cermic tube) 玻璃管或陶瓷管必须无缺陷、缺损、凹陷,明显脏污。(The glass tube should be of no blemish, no damage and no pollution.) 4.2铜帽(Copper cap) 每个铜帽必须焊接牢固,导电性良好,表面镀层结合牢固,不易脱落,无损伤。浸入温度为15-35℃的水中24小时,按标准的要求施加轴向拉力5N,并持续1分钟,不会出现松动、松脱的情况。(Every copper cap must be welded tightly and have good electric conductivity. Also the outer coating can be very tight, perfect and not easily fallen off. It can be immersed in water with temperature between 15-35℃for 24 hours. Every copper cap can stand axial pulling force 5N exercised by special equipment for minute.) 4.3焊锡(solder) 焊料应具有良好的电接触性能,并且在正常使用时不应有熔化的迹象。(The welding materials should have good electric conductivity and not be melted at normal using.) 4.4引线(Lead pigtail) 引线采用镀锡铜线,具有良好的可焊性能,导电性能。可焊性符合GB2423.28-82 /IEC68-2-20之标准。引线的尺寸以及形状可以根据客户的不同要求制作。(Lead should be tinned and have the performance of perfect welding and good contact with electricity.Jionting performance apply for GB2423.28-82/IEC68-2-20 standard) 5.电气性能(Electricity function) 5.1测试具备的环境条件如下(The environment condition of the test):

| |||||||||||||||||||||||||

5.2测试仪器具备的条件如下(The requirement of the testing equipment):

C.并应使用符合标准的测试制具来安装保险丝。(The test fixtures must meet IEC60127 standard.) 5.3时间/电流测试(Time/electrical characteristics test) 对保险丝通以2.1倍的额定电流时,保险丝应该在120 s之内动作;通以2.75倍的额定电流时,保险丝应该在0.4 s~10 s之内动作;通以4倍的额定电流时,保险丝应该在150ms~3s之内动作;通以10倍的额定电流时,保险丝应该在20ms~150ms之内动作;并且已动作的保险丝不会出现再导通损坏的情况。 Fuse shall open in not more than 120s at 210%of rated current ;Fuse shall open in not less than 0.4 s or morn than 10 s at 275% of rated current; Fuse shall not open in not less than 150ms or morn than 3 s at 400% of rated current; Fuse shall open in not less than 20ms or more than 150ms o at 1000% of rated current .These opened fuse shall be no tracking or re-establishment of the circult.

| |||||||||||||||||||||||||

5.4耐久性试验(Endurance test) 对保险丝通过1.0In电流1小时,然后断电15分钟,此为一个循环,如此经过100次循环后,再对保险丝通以1.5In持续1小时,此测试完成后,再量保险丝两端的电压降,此数值不超出10%的变化。并且相关数据不能超出规格表中的要求。同时在测试过程中不能出现保险丝断开的情况。 Fuse shall carry 100% of rated current continuously for1 hour.Immediately after,The current is switched off for 15 minutes. This cycle is repeated 100 times. After 100 cycles, Fuse shallcarry 150% of rated currend continuously for1 hour.Immediately after,Fuse shall carry 100% of rated currendin order to measurethe fuse voltage drop. the voltage drop shall not be deviated from the value before endurance test by more than 10% and the value can not exceed the standard list. Meanwhile, the fuse can not open during the above tests. 规格表

5.5分断能力测试(Breaking capacity test) 分断能力35AOR 10In,选较大的值,相关线路应符合IEC60127之相关标准。 Rated breaking capacity :35A or 10In ,whichever is greater,tested with a.c and circuit apply for IEC60127. 5.6盐雾测试(Salt test) 将保险丝进行4小时的盐雾测试时,保险丝不会出现明显变色的现象。 The fuses shall remain in the humidity chamber when testing cannot be completed in a 4 hrs period. | |||||||||||||||||||||||||