-

图文详情

-

产品属性

-

相关推荐

◆Viewing angle:120 deg

发光角度:120℃

◆The materials of the LED dice is InGaN

芯片成分

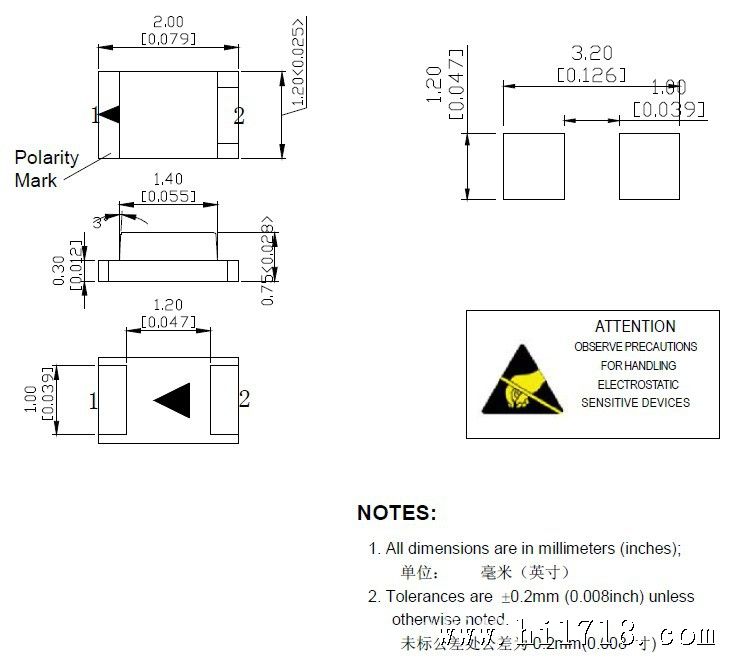

◆2.0mm×1.2mm×0.75mm SMT-LED

外型尺寸

◆Lens Appearance: Water Clear

胶体颜色:水色透明

◆ RoHS compliant lead-free soldering compatible

符合ROHS(危害物质禁用指令)要求。

※Absolute maximum ratings at Ta=25℃额定值

Parameter 参数 | Symbol 符号 | Value 值 | Unit 单位 |

Power dissipation功率耗损 | Pd | 65 | mW |

Forward current正向电流 | If | 30 | mA |

Reverse voltage反向电压 | Vr | 5 | V |

Operating temperature range工作温度范围 | Top | -40~+85 | ℃ |

Storage temperature range贮存温度范围 | Tstg | -40~+100 | ℃ |

Peak pulsing current脉冲电流 | Ifp | 100 | mA |

Electrostatic Discharge抗静电能力 | ESD | 2000(HBM) | V |

NOTE: IFP Conditions: Pulse Width≦10msec. and Duty cycle≦1/10.

IFP条件:脉冲持续时间≦10msec,占空因素≦1/10

※ Electrical-optical characteristics at Ta=25℃电性光电特性

Parameter 参数 | Test Condition 测试条件 | Symbol 符号 | Value值 | Unit 单位 | ||

Min. | Typ. | Max. | ||||

Forward voltage 正向电压 | If=20mA | VF | 2.0 | -- | 2.4 | V |

Luminous intensity 发光强度 | If=20mA | Iv | 150 | -- | 200 | mcd |

Dominant wavelength 主波长 | If=20mA | WLD | 620 | -- | 630 | nm |

Viewing angle at 50% Iv 半功率角 | If=20mA | 2 θ 1/2 | -- | 120 | -- | Deg |

Reverse current 反向电流 | Vr=5V | Ir | -- | -- | 10 | mA |

NOTE: 1. Tolerance of luminous intensity is±10%

发光强度公差为±10%

2. Tolerance of forward voltage is±0.05V

正向电压公差±0.05v

信赖性试验

| 试验类别Classification | 试验项目 Test Item | 试验条件 Test Condition | 试验设备 Test Equipment | 样品数 Sample Size | 失败率 Failure Rate |

| 耐久性试验 Endurance Test | 室温通电试验 Operation Life | Temp=(25±5)℃ RH=(50±10)%IF=20mA or 30mA or 50mACheck point: 0hr; 125hrs; 500hrs; 1000hrs | 烧机板 Burn in board | 20 | 0 |

| 高温高湿储存试验 High Temperature High Humidity Storage | Temp=(85±5)℃ RH=(90%~95%) Check point: 0hr; 125hrs; 500hrs; 1000hrs | 可程式恒温恒湿试验机 Programmable Temp & Humidity Chamber | 20 | 0 | |

| 高温高湿反向耐压试验 High Temperature High HumidityReverse Bias | Temp=(85±5)℃ RH=(90%~95%) VR=5V Check point: 0hr; 125hrs; 500hrs; 1000hrs | 可程式恒温恒湿试验机 DC=5V电源Programmable Temp & Humidity ChamberPower:DC=5V | 20 | 0 | |

| 高温储存试验 High Temperature Storage | High Temp=(85±5)℃ Check point: 0hr; 125hrs; 500hrs; 1000hrs | 烤箱 Oven | 20 | 0 | |

| 低温储存试验 Low Temperature Storage | Low Temp=(-30±5)℃ Check point: 0hr; 125hrs; 500hrs; 1000hrs | 可程式恒温恒湿试验机 Programmable Temp & Humidity Chamber | 20 | 0 | |

| 环境试验 EnvironmentalTest | 温度循环试验 Temperature Cycle Test | (85±5) ℃ ~ ( -30℃±5) ℃ ~ (85±5) ℃30min 120min 30 min 100minTest time: 0 cycle 10cycle 50cycle 100cycle | 可程式恒温恒湿试验机 Programmable Temp & Humidity Chamber | 20 | 0 |

| 冷热冲击试验 Thermal Shock Test | (110±5) ℃ ~ ( -30℃±5) ℃ ~ (110±5) ℃15min 8min 15 min 8minTest time: 0 cycle 10cycle 50cycle 100cycle | 气体式冷热冲击试验机 Thermal Shock Tester (Air to Air) | 20 | 0 | |

| 回流焊试验 Solder Resistance | Temp=260±5℃ Dwell Time=10±1sec; Test times=5 times | 回流焊试验机 Reflow Oven | 20 | 0 | |

| 焊接特性试验 Solder ability | Temp=230±5℃ Dwell Time=5±1sec; | 锡炉 Tin furnace | 20 |

※Precautions for use使用规范

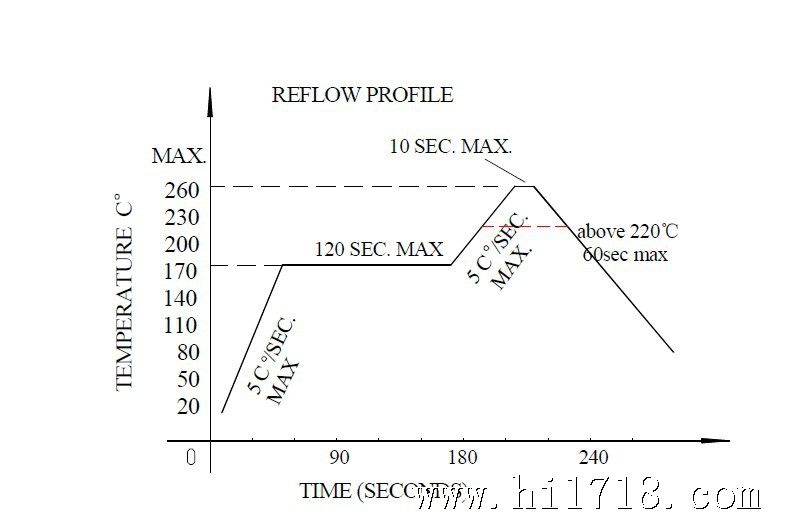

Reflow Profile回流焊规范

Pb-free Solder temperature Profile无铅产品回流焊温度条件曲线规范

Note: a)Reflow soldering should not be done more than two times.

材料焊接次数不超过2次。

b)Do not put stress on the LEDs when soldering.

焊接时请不要重压LED灯。

c)Do not warp the circuit board before it have been returned to normal ambient conditions

after soldering.

焊接后温度未回降到常温时请勿扭曲线路板。

Hand Soldering Profile手工焊接规范

The temperature of the iron should be lower than 300℃and soldering within 3sec per solder-pad

is to be observed.

手工焊接时,烙铁温度不高于300℃,每个焊脚焊接时间不超过3秒

Storage Profile贮存规范

1. Do not open the moisture proof bag before ready to use the LEDs

请在未准备使用LED之前不要打开防静电袋子。

2. The LEDs should be kept at 30℃or less and 60%RH or less before opening the package.

The max. storage period before opening the package is 1 year.

LED在未开封之前应保存在30℃以下,湿度在60%以下的环境中,长保存期为1年。

3. After opening the package, the LEDs should be kept at 30℃/40%RH or less, and it should be

used within 7 days

打开包装待后,LED需保存在30℃/40%湿度以下的条件,且必须在7天内使用完。

4. If the LEDs be kept over the condition of 3, baking is required before mounting. Baking

condition as below: 60±5℃for 12 hours

如果LED超出了第3点要求,则LED必须经过烘烤才能使用,烘烤条件为:60±5℃,12个

小时