-

图文详情

-

产品属性

-

相关推荐

Thermo Scientific* Gilmont* 65mm Construction Industrial Direct Reading Flowmeters With Standard w/standard valve; Air flow rate: 5 to 60SmL/min.

具体参数如下:

5FL4OWMETERSInternational

FLOWMETERS

Rotameter Introduction

Corrections for Gas Flow

Gas Flow from Air Flow:

Corrections for Liquid Flow

Liquid Flow from Water Flow:

Corrections for Temperature and Pressure:

Correction for Temperature

(Note: for liquids the effect of pressure is negligible):

General Correction equations for approximating gas

or liquid flow from air or water flow readings.

IMPORTANT INFORMATION ON ROTAMETERS

The Variable-Area type flowmeter, or Rotameter, is one

of the most economical and reliable of flow

measurement instruments. In various configurations it

can be designed to withstand high pressures, corrosive

fluids, high temperatures, and is completely

independent of factors influencing electronic meters.

They can be calibrated to measure nearly any gas or

liquid, because their principles of operation are simple

and well understood. The flow indication is obtained

from a balance of the fluid forces underneath the float

with gravity.

This is done using a uniformly tapered tube, a float

whose diameter is nearly identical to the tube ID at the

inlet, and a scale to correlate float height. The flow tube

is traditionally placed in a vertical position and fluid

enters from the bottom, forcing the float up in the tube

until a sufficient annular opening exists between the

float and tube to allow the total volume of fluid to flow

past the float. At this point the float is in an equilibrium

position and its height is proportional to the flow rate.

DENSITY TERMS

= density of gas in gm/ml at std. cond.

= density of liquid in gm/ml at std. cond.

= density of liquid in gm/ml at T

= density of float = 2.53 for glass, 3.98 for ruby,

8.02 for stainless steel, 14.9 for tungsten carbide

VISCOSITY TERMS

= viscosity of gas in cp at std. cond.

= viscosity of liquid in cp at std. cond.

= viscosity of liquid in cp at T

FLOWM5ETER5S

Multiply

Reading ByWorking Pressure of Flowmeter – PSIG

Pressure at Which Meter Was Calibrated – PSIG

FLOWMETER PRESSURE CORRECTION

SPECIFIC GRAVITY CORRECTION FACTORS

Laboratory Flowmeters

FLOWMETERS

• High-accuracy correlated flowmeters – ±2% of reading!

• Wide selection of flow ranges—measure air from 0.02 ml/min to

675 LPM or water from 0.0002 ml/min to 20 LPM

• Excellent chemical compatibility with glass and PTFE construction

Product Description

Unshielded Flowmeters

Choose unshielded flowmeters for high purity and corrosion resistance in

low-pressure applications. PTFE stops accept taper joints to make quick

glass-to-glass connections.

PRODUCT SPECIFICATIONS

Flow rate* Unshielded flowmeters Shielded flowmeters Shielded flowmeters with valves

Tube Float Air Water Catalog Catalog Ports Catalog Ports

size included (ml/min) (ml/min) number Max psi number NPT(M) Max psi number NPT(M) Max psi

10 Glass 0.2-90 0.002-1.1 GF-2000 15 GF-2060 1⁄4" 125 GF-9060 1⁄8" 125

316 SS 0.36-160 0.004-2.3

11 Glass 1-280 0.01-4.0 GF-2100 15 GF-2160 1⁄4" 125 GF-9160 1⁄8" 125

316 SS 2-500 0.02-8.6

12 Glass 20-2100 0.4-40 GF-2200 15 GF-2260 1⁄4" 100 GF-9260 1⁄8" 100

316 SS 36-3700 0.86-86

13 Glass 200-14,000 2-300 GF-2300 15 GF-2360 1⁄4" 75 GF-9360 1⁄8" 75

316 SS 360-25,000 4-640

14 Glass 1000-36,000 10-850 GF-2400 15 GF-2460 1⁄2" 60 GF-9460 1⁄4" 60

316 SS 1800-64,000 21-1820

15 Glass 3000-77,000 30-1900 GF-2500 15 GF-2560 1⁄2" 50 GF-9560 1⁄4" 50

316 SS 5300-137.000 64-4100

NOTE: For pressure drop of each flowmeter, please call our Application Specialists. *When using stainless steel float, refer to included correlation table for proper reading.

Flow rate* Unshielded flowmeters Shielded flowmeters Shielded flowmeters with valves

Tube Float Air Water Catalog Catalog Ports Catalog Ports

size included (ml/min) (ml/min) number Max psi number NPT Max psi number NPT Max psi

Micro Ruby 0.02-15 0.0002-0.12 GF-3000 15 GF-3060 1⁄4 (M) 125 GF-9760 1⁄8 (M) 125

0 Glass 0.2-100 0.002-1.1 GF-1000 15 GF-1060 1⁄4 (M) 125 GF-7060 1⁄8 (M) 125

316 SS 0.36-180 0.004-2.3

1 Glass 1-280 0.01-4.0 GF-1100 15 GF-1160 1⁄4 (M) 125 GF-7160 1⁄8 (M) 125

316 SS 2-500 0.02-8.6

2 Glass 10-1900 0.2-36 GF-1200 15 GF-1260 1⁄4 (M) 100 GF-7260 1⁄8 (M) 100

316 SS 20-3400 0.43-77

3 Glass 200-14,000 3-300 GF-1300 15 GF-1360 1⁄4 (M) 75 GF-7360 1⁄8 (M) 75

316 SS 360-25,000 6-640

4 Glass 1000-36,000 10-850 GF-1400 15 GF-1460 1⁄2 (M) 60 GF-7460 1⁄4 (M) 60

316 SS 1800-64,000 21-1820

5 Glass 3000-77,000 30-1900 GF-1500 15 GF-1560 1⁄2 (M) 50 GF-7560 1⁄4 (M) 50

316 SS 5300-137,000 64-4100

6 Glass 25,000-330,000 500-8000 — — GF-1660 1⁄2 (F) 50 — — —

316 SS 50,000-675,-20,000

Shielded Flowmeters

Use these flowmeters for higher pressure applications. The clear polycarbonate

shield adds strength and protects the tube from damage.

Fluid contacts only the borosilicate glass tube, PTFE body, and VITON®

fluoroelastomer O-rings. End bushings are polypropylene with PTFE inserts.

Shielded Flowmeters with Valves

Choose these flowmeters for greater control; micrometer capillary valves ensure

precise, reproducible measurement and flow control. Shields are clear

polycarbonate; valve consists of a precision-bore glass tube for the fluid and a

precision-ground rod of PCTFE (PTFE for sizes 4, 5, 14, and 15). The 20-turn

micrometer valve can be adjusted from 0.1 to 100% of maximum flow. You can

interchange flowtubes among valve assemblies of the same size.

Direct Reading Flowmeters

Read air and water flow directly with these compact meters. Accuracy is ±5% of

reading or 2 mm of the scale length, whichever is greater.

Correlated Flowmeters

Extremely accurate . . . . ± 2% of reading or ±1 scale division, whichever is

greater. Determine flow values for air and water from the computerized

calibration table enclosed with each flowmeter. Tables are included. See page 58

to order our flow analysis software to generate flow charts specific to your

individual applications.

For technical application

questions, contact Barnant

at 800-637-3739

Direct Reading Correlated

Accuracy:±5% of reading or 2mm of scale length whichever is greater. ±2% of reading or ±1 scale division, whichever is greater.

For micro: ±5% of reading or ±2 scale division

(Air); ±10% of reading or ±3 scale division (water).

Repeatability:±1% of reading or ±0.5 scale division, whichever is greater.

Turndown Ratio:Better than 25:1

Pressure Rating:See tables, page 56

Operating Temperatures:-15°F to 150°F (-26°C to 65°C) at full pressure rating.

Connections:Unshielded Use Taper Joint Adapters–see chart at right

Shielded 3/8” I.D. tubing on Sizes 0-3, and Micro to 13,

5/8” I.D. tubing on Sizes 4-5, and 14 to 15, or see

chart at right for coupling adapters.

Shielded with Valve 1/8” NPT(M) Sizes 0-3, Micro–13

1/4” NPT(M) Sizes 4-5, 14-15

Shipping Weight:Unshielded 0.5 lb. (0.3 kg)

Shielded 1.0 lb. (0.5 kg)

Shielded with Valve 1.0 lb. (0.5 kg)

GF-4004Flowmeter stand kit. Includes one base, one rod, and two mounting clamps

GF-4001Flowmeter base

GF-4002Rod, 18"L

GF-4003Mounting clamp. Includes wood screws

Laboratory Flowmeters

FLOWMETERS

PRODUCT SPECIFICATIONS

MATERIALS OF CONSTRUCTION

Borosilicate glass Flowtube

Glass/316 SS (Ruby-micro size only) Floats

PTFE End blocks/stops

PTFE Inlet/Outlet

Polycarbonate Shield

Polypropylene Shield ends

PTFE, PCTFE, Glass Valve

Viton®O-rings

DIMENSIONS

Dimensions

Unshielded Shielded Shielded with valves

Flowmeter Stand Kit and Components

The flowmeter stand kit contains everything you need to mount your GILMONT®

flowmeter on a stand, a benchtop, or a wall. The base is machined from rugged

aluminum. A built-in ‘‘bubble level’’ ensures that the base is level for maximum

accuracy. Configure base to accept three rod and clamp assemblies for

unshielded or shielded flowmeters. Mount valved flowmeters directly—base

accepts two large flowmeters (size 4, 5, 14, or 15) or three of the smaller

flowmeters. Mounting clamps hold flowmeters firmly in place without obstructing

your view of the flowmeter scale or damaging the flowtube or shield.

Clamps are L-shaped with mounting holes bored into them for mounting

flowmeters to a wall or panel (wood screws included).

TAPER JOINTS AND PTFE COUPLING ADAPTERS

Cat. No. Tube Size Connection

Taper joints for unshielded flowmeters

GF-1121 Micro., 0, 10/30 taper

1, 10, 11

GF-1221 2 and 12 12/30 taper

GF-1321 3 and 13 14/35 taper

GF-1421 4 and 14 19/38 taper

GF-1521 5 and 15 24/40 taper

PTFE coupling adapters for shielded flowmeters

GF-4010 Micro., 0, 1, 2, 1/4” NPT(F)

3, 10, 11, 12, 13

GF-4020 4, 5, 14, 15 1/2” NPT(F)

For technical application

questions, contact Barnant

at 800-637-3739

Accessories

GF-4001 Flowmeter Baseis made of rugged

aluminum. Mount flowmeters directly—base accepts

three flowmeters. Built-in bubble level.

GF-4000 Flowrate Analysis Softwaremakes

flow analysis simple. You can produce flow rate

tables and custom scales based on your temperature,

pressure, viscosity and density conditions; float

material; and the gas or liquid being measured.58

Max flow rate 65mm, 303 stainless steel flowmeters

(ml/min) Without valves With precision valves

Air Cat. no. Cat. no.

Glass 95 1.1 100 GF-6340-1100 GF-6341-1100

SS 230 4.9

Glass 280 3.9 110 GF-6340-1110 GF-6341-1110

SS 620 15

Glass15 GF-6340-1115 GF-6341-1115

SS 2000 55

Glass20 GF-6340-1120 GF-6341-1120

SS

Glass 125 GF-6340-1125 GF-6341-1125

SS 12,000 360

Glass 14, GF-4340-1130 GF-4341-1130

SS 25,000 800

Glass 25, GF-4340-1135 GF-4341-1135

SS 46,

•• •www..com

Gilmont®Accucal®Flowmeters

FLOWMETERS

• Correlated and direct reading all in one easy-to-read meter

• Accuracy up to ±2% of reading!

• Interchangeable scales—customize your application

• Extremely low pressure drops—ideal for procedures with

critical pressure values

Two direct reading

scales are included with

each flowmeter. (English

and metric units)

These flowmeters can be

mounted on a panel or base.

Correlated and Direct Readingin one easy to use flowmeter. Each meter includes

correlation charts for air and water and two direct-reading scales—an air scale and a water

scale. Easily change between correlated and direct-reading scales depending on your application.

Meters are available in 65mm and 150mm scale lengths.

Each direct-reading scale indicates flow rates in metric and English units, for both glass and

stainless steel floats under standard operating conditions. Use the new GF-4000 software to create

your own custom scales.

Excellent Accuracyis achieved with our second-generation correlation techniques

and the factory calibration of the tube. Accuracy can be expressed as a percent of

reading—not of full-scale! With correlated use, accuracy is ±2% of reading or ±1%

scale division, whichever is greater. With direct-reading use, ±2 divisions accuracy is

±5% of reading or ±3 mm on scale, whichever is greater. All flowtubes have serial

numbers for traceability to calibration, accuracy, and manufacturing data.

Quality Industrial Designensures use in most tough applications. The clear polycarbonate

front shield provides a 90° view of the scales on the stainless meters.

Meters are designed for easy flowtube exchange or replacement. The end stop has a large diameter

to let you center the flowtube quickly and more accurately than most flowmeters. All flowtubes

are interchangeable within the same frame size. Call our Application Specialist to order a

replacement flowtube or to upgrade your unit.

Mount flowmeters on a panel or on our flowmeter base (see below). Invert frame for vacuum

applications or when back pressure compensation is required.

Advanced Metering Valvesare available with GILMONT®flowmeters. The shallow

taper design gives you linear control over 80% of the usable range. Valves are 14-turn.

NOTE: For pressure drop of each flowmeter, please call our Application Specialists.

H2O

Float

Tube

sizeFor technical application

questions, contact Barnant

at 800-637-3739

150-mm, 303 stainless steel flowmeters

Tube Without valves With precision valves

size Cat. no. Cat. no.

200 GF-6540-1200 GF-6541-1200

210 GF-6540-1210 GF-6541-1210

215 GF-6540-1215 GF-6541-1215

220 GF-6540-1220 GF-6541-1220

225 GF-6540-1225 GF-6541-1225

230 GF-6540-1230 GF-6541-1230

235 GF-6540-1235 GF-6541-1235

240 GF-6540-1240 GF-6541-1240

250 GF-6540-1250 GF-6541-1250

Max flow rate (ml/min)

Air

Glass 95 1.1

SS 230 4.9

Glass 280 3.9

SS 620 15

Glass 1000 17

SS 2000 55

Glass 2200 43

SS

Glass

SS 12,000 360

Glass 14,000 320

SS 25,000 800

Glass 25,000 590

SS 46,

Glass 40,000 960

SS 73,

Glass 85,

SS 150,

H2O

59

Gilmont®Accucal®Flowmeters

FLOWMETERS

▼

▼

Accuracy:The greater of ±2% of reading or ±1 division

(correlated use); the greater of ±5% of reading

±2 division of scale (direct reading use)

Repeatability:±1% of reading or ±0.5 scale division,

whichever is greater

Turn-Down Ratio:Better than 25:1

Maximum Pressure:200 psig at 250°F

Maximum Operating Temperature:250°F (121°C)

Connections:1⁄4" NPT(F) for 240 and 250 tube sizes;

1⁄8 NPT(F) for all others

Shipping Weight:65mm flowmeters: 1 lb (0.5 kg)

150mm flowmeters: 2 lb (1.0kg)

*Other Floats/materials available. Call our application specialists for details.

Mount these flowmeters

on a panel or base.

Flowmeter base

GF-4001

PRODUCT SPECIFICATIONS

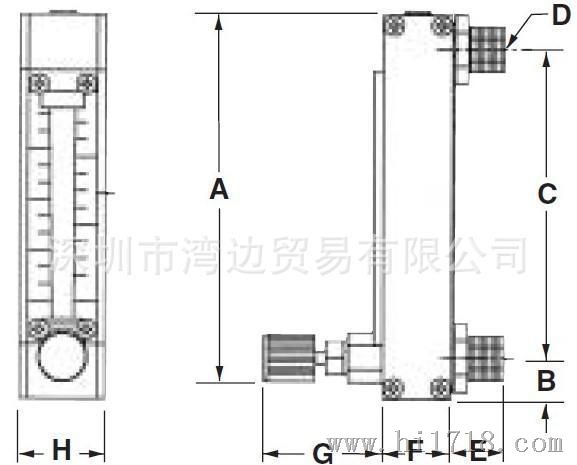

DIMENSIONS

Flowmeter End Inlet/Outlet

Type Flowtube Floats Blocks Connections Valve O-rings

303 SS Borosilicate glass Glass/316 SS 303 SS 303 SS PCTFE/PTFE Viton®

(303 SS PCTFE/PTFE

for tube sizes 240 and 250)

MATERIALS OF CONSTRUCTION

Dimensions - inches (mm)

Flowmeter A B C D E F G H

65 mm scale (all tube sizes) 5.65 (143.5) 0.60 (15.2) 4.50 (114.3) 1/8 - 27 NPT 0.78 (19.8) 1.00 (25.4) 1.75 (44.4) 1.25 (31.7)

150 mm scale (200-235 tubes) 10.02 (254.5) 0.60 (15.2) 8.81 (223.8) 1/8 - 27 NPT 0.78 (19.8) 1.00 (25.4) 1.75 (44.4) 1.25 (31.7)

150 mm scale (240-250 tubes) 12.64 (321.1) 0.79 (20.1) 11.00 (279.4) 1/8 - 27 NPT 0.95 (24.1) 1.50 (38.1) 2.13 (54.1) 1.75 (44.4)

Float

For technical application

questions, contact Barnant

at 800-637-3739

60•• •www..com

Industrial Flowmeters

FLOWMETERS

• Accuracy: ± 5% of full scale, 0.5% of scale repeatability

• Flow ranges: Air – 1 cc to 60 L/MIN, 0.025 cc to 1.8 L/MIN

water

• Pressure ratings to 200 psig (max.)

• Temperature ratings to 250°F (max.)

• Calibrated (mm scale) or direct reading (metric)

• Ten to one flowrange on all units

For All Your Industrial and

Laboratory Applications

Product Description

Choose GILMONT®flowmeters for all your industrial and laboratory

applications. Measure and control liquids and gases in a wide range of

applications with precision and repeatability.

Gilmont offers flowmeters in a variety of materials, including Aluminum,

Brass, and SS Standard and high precision metering valves, and a wide

range of direct reading scales are available for most models.

The 65mm and 150mm series have precision glass metering tubes,

glass and SS floats. Front shields have 1.5X magnification for more

accurate readings.

These flowmeters follow industry standard dimensions for easy

retrofitting and direct replacements. Standard panel mounting hardware

is supplied with each meter, and tripod bases are available for benchtop

applications. Order part number GF-8008

65 mm Calibrated

This 65mm size incorporates all features and quality of the larger

flowmeters, in a compact size. All tubes are protected within the unitized

holder and strong aluminum frame. A lens magnifier makes the

scales easy to read. Calibration tables for both air and water are

enclosed with each flowmeter.

65 mm Direct Reading

Utilizing a vast reference library of liquids and“noble” gases, we are

able to provide flowmeters to meet specific, rather than general, flow

ranges. All Direct Reading 65mm flowmeters are available in liters for

international applications and acceptance.

150 mm Calibrated

This versatile meter is functionally and dimensionally interchangeable

with other current designs while providing many innovative features.

The glass metering tubes have integral float guides to assure a ±5%

accuracy of full scale. Glass and Stainless Steel floats are standard.

Calibration tables for both air and water are enclosed with each

flowmeter.

Materials of Construction

• Wetted End Blocks, Fittings and Internal Parts –

Anodized Aluminum, Brass, 316 SS.

• Seal Materials – Buna-N or Viton®.

• Side Plates – Aluminum

• Metering Tube – Borosilicate Glass enclosed in the

Unitized Aluminum Frame

• Piping Connections – Aluminum, Brass or 316SS,

1/8 NPT(F) horizontal on inlet and outlet.

• Float Material – Black Glass, 316 SS

or Tungsten Carbide

150mm Construction max. operating operating flow rate scale reading of full scale and water

PRODUCT SPECIFICATIONS

65 & 150 mm Flowmeters

Dimensional Drawing

Max Flow

SML / min

Air WATER ALUMINUM BRASS STAINLESS ALUMINUM BRASS STAINLESS ALUMINUM BRASS STAINLESS

STEEL STEEL STEEL

8.1 - 145 0.1 - 2.4 GF-8320-1001 GF-8330-1001 GF-8340-1001 GF-8321-1001 GF-8331-1001 GF-8341-1001

30.2 - 298 0.46 - 7.7 GF-8320-1002 GF-8330-1002 GF-8340-1002 GF-8321-1002 GF-8331-1002 GF-8341-1002

45 - 522 0.8 - 12 GF-8320-1101 GF-8330-1101 GF-8340-1101 GF-8321-1101 GF-8331-1101 GF-8341-1101

28 - 1249 0.6 - 27 GF-8320-1201 GF-8330-1201 GF-8340-1201 GF-8321-1201 GF-8331-1201 GF-8341-1201

90 - 2520 3.7 - 71 GF-8320-1202 GF-8330-1202 GF-8340-1202 GF-8321-1202 GF-8331-1202 GF-8341-1202

845 - 6318 4 - 147 GF-8320-1401 GF-8330-1401 GF-8340-1401 GF-8321-1401 GF-8331-1401 GF-8341-1401

1973 - 364 GF-8320-1402 GF-8330-1402 GF-8340-1402 GF-8321-1402 GF-8331-1402 GF-8341-1402

2272 - 745 GF-8320-1501 GF-8330-1501 GF-8340-1501 GF-8321-1501 GF-8331-1501 GF-8341-1501

6082 - 1866 GF-8320-1502 GF-8330-1502 GF-8340-1502 GF-8321-1502 GF-8331-1502 GF-8341-1502

5 - 100 GF-8320-2009 GF-8330-2009 GF-8340-2009 GF-8321-2009 GF-8331-2009 GF-8341-2009

20 - 250 GF-8320-2010 GF-8330-2010 GF-8340-2010 GF-8321-2010 GF-8331-2010 GF-8341-2010

20 - 500 GF-8320-2109 GF-8330-2109 GF-8340-2109 GF-8321-2109 GF-8331-2109 GF-8341-2109

100 - 1000 GF-8320-2110 GF-8330-2110 GF-8340-2110 GF-8321-2110 GF-8331-2110 GF-8341-2110

500 - 10000GF-8320-2410 GF-8330-2410 GF-8340-2410 GF-8321-2410 GF-8331-2410 GF-8341-2410

2000 - 40000GF-8320-2510 GF-8330-2510 GF-8340-2510 GF-8321-2510 GF-8331-2510 GF-8341-2510

0.025 - 0.5 GF-8320-2004 GF-8321-2004 GF-8330-2004 GF-8331-2004 GF-8340-2004 GF-8341-2004

0.4 - 6 GF-8320-2014 GF-8330-2014 GF-8340-2014 GF-8321-2014 GF-8331-2014 GF-8341-2014

1 - 25 GF-8320-2114 GF-8330-2114 GF-8340-2114 GF-8321-2114 GF-8331-2114 GF-8341-2114

5 - 60 GF-8320-2214 GF-8330-2214 GF-8340-2214 GF-8321-2214 GF-8331-2214 GF-8341-2214

20 - 250 GF-8320-2414 GF-8330-2414 GF-8340-2414 GF-8321-2414 GF-8331-2414 GF-8341-2414

100 - 1500 GF-8320-2516 GF-8330-2516 GF-8340-2516 GF-8321-2516 GF-8331-2516 GF-8341-2516

8.1 - 140 0.12 - 2.34 GF-8520-1100 GF-8530-1100 GF-8540-1100 GF-8521-1100 GF-8531-1100 GF-8541-1100 GF-8522-1100 GF-8532-1100 GF-8542-1100

33 - 264 0.28 - 4.7 GF-8520-1200 GF-8530-1200 GF-8540-1200 GF-8521-1200 GF-8531-1200 GF-8541-1200 GF-8522-1200 GF-8532-1200 GF-8542-1200

70 - 825 0.8 - 16 GF-8520-1300 GF-8530-1300 GF-8540-1300 GF-8521-1300 GF-8531-1300 GF-8541-1300 GF-8522-1300 GF-8532-1300 GF-8542-1300

201 - 1682 3.5 - 46 GF-8520-1406 GF-8530-1406 GF-8540-1406 GF-8521-1406 GF-8531-1406 GF-8541-1406 GF-8522-1406 GF-8532-1406 GF-8542-1406

480 - 4562 5.4 - 133 GF-8520-1500 GF-8530-1500 GF-8540-1500 GF-8521-1500 GF-8531-1500 GF-8541-1500 GF-8522-1500 GF-8532-1500 GF-8542-1500

288 - 7590 6 - 217 GF-8520-1606 GF-8530-1606 GF-8540-1606 GF-8521-1606 GF-8531-1606 GF-8541-1606 GF-8522-1606 GF-8532-1606 GF-8542-1606

462 - 541 GF-8520-1700 GF-8530-1700 GF-8540-1700 GF-8521-1700 GF-8531-1700 GF-8541-1700 GF-8522-1700 GF-8532-1700 GF-8542-1700

3542 - 1881GF-8520-1800 GF-8530-1800 GF-8540-1800 GF-8521-1800 GF-8531-1800 GF-8541-1800 GF-8522-1800 GF-8532-1800 GF-8542-1800

1 - 100 GF-8520-2117 GF-8530-2117 GF-8540-2117 GF-8521-2117 GF-8531-2117 GF-8541-2117 GF-8522-2117 GF-8532-2117 GF-8542-2117

20 - 200 GF-8520-2217 GF-8530-2217 GF-8540-2217 GF-8521-2217 GF-8531-2217 GF-8541-2217 GF-8522-2217 GF-8532-2217 GF-8542-2217

50 - 800 GF-8520-2317 GF-8530-2317 GF-8540-2317 GF-8521-2317 GF-8531-2317 GF-8541-2317 GF-8522-2317 GF-8532-2317 GF-8542-2317

200 - 2500 GF-8520-2417 GF-8530-2417 GF-8540-2417 GF-8521-2417 GF-8531-2417 GF-8541-2417 GF-8522-2417 GF-8532-2417 GF-8542-2417

400 - 4800 GF-8520-2517 GF-8530-2517 GF-8540-2517 GF-8521-2517 GF-8531-2517 GF-8541-2517 GF-8522-2517 GF-8532-2517 GF-8542-2517

800 - 10000GF-8520-2617 GF-8530-2617 GF-8540-2617 GF-8521-2617 GF-8531-2617 GF-8541-2617 GF-8522-2617 GF-8532-2617 GF-8542-2617

1000 - 23000GF-8520-2717 GF-8530-2717 GF-8540-2717 GF-8521-2717 GF-8531-2717 GF-8541-2717 GF-8522-2717 GF-8532-2717 GF-8542-2717

5000 - 60000GF-8520-2817 GF-8530-2817 GF-8540-2817 GF-8521-2817 GF-8531-2817 GF-8541-2817 GF-8522-2817 GF-8532-2817 GF-8542-2817

0.5 - 10 GF-8520-2227 GF-8530-2227 GF-8540-2227 GF-8521-2227 GF-8531-2227 GF-8541-2227 GF-8522-2227 GF-8532-2227 GF-8542-2227

1 - 20 GF-8520-2327 GF-8530-2327 GF-8540-2327 GF-8521-2327 GF-8531-2327 GF-8541-2327 GF-8522-2327 GF-8532-2327 GF-8542-2327

1 - 50 GF-8520-2427 GF-8530-2427 GF-8540-2427 GF-8521-2427 GF-8531-2427 GF-8541-2427 GF-8522-2427 GF-8532-2427 GF-8542-2427

10 - 200 GF-8520-2627 GF-8530-2627 GF-8540-2627 GF-8521-2627 GF-8531-2627 GF-8541-2627 GF-8522-2627 GF-8532-2627 GF-8542-2627

20 - 500 GF-8520-2727 GF-8530-2727 GF-8540-2727 GF-8521-2727 GF-8531-2727 GF-8541-2727 GF-8522-2727 GF-8532-2727 GF-8542-2727

150 - 1200 GF-8520-2827 GF-8530-2827 GF-8540-2827 GF-8521-2827 GF-8531-2827 GF-8541-2827 GF-8522-2827 GF-8532-2827 GF-8542-2827

FLOWM6ETER1S